Forge: dual burner propane

Tools use: Hammer and flat tongs

Steel: 1080

Normalization: Vermiculite

Quench: Used motor oil

Temper: Twice at 400 degrees Fahrenheit

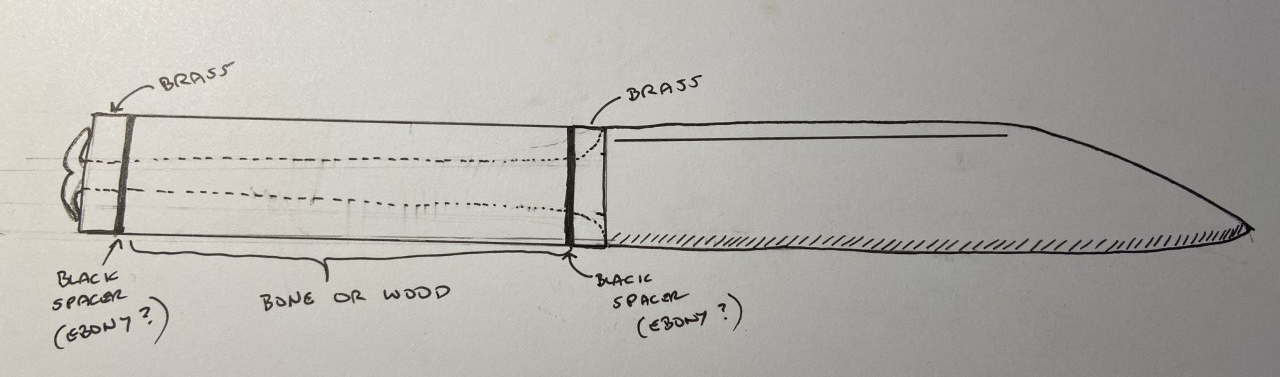

Procedure: Forge blade into desired shape, grind on belt sander to final shape, set blade geometry, normalize, quench, sharpen, add hardware, peen tang.

This was my first attempt at forging a knife, as well as creating a sheath and brass work. There were mistakes made (like using the vise to hold wet leather in place resulting in a rust stain on the leather). The blade is a bit too thick…I should have drawn it out more and I am not happy with hose the end of the handle turned out. But all in all, I am happy with it and think it was a good first attempt. It is sharp by the way and it is hungry for blood…since it ate my finger a few times while I was sharpening it.