I also do a little blacksmithing and find it a bit cathartic to beat metal into the shape you want…if not also physically demanding. My first official project was HRM Morgan’s Kings Sigil. I worked with Master Bran Padrig (SCA, Kingdom of Atenveldt) and after helping me with the first two troll crosses, he turned me loose with minimal supervision and I completed a total of 21 crosses. My next project (which spanned a year) was the making of a forging hammer in the style of the Mästermyr find. After that, I did not do much more beyond that (I did make a set of crucible tongs and a set of flat tongs…which is now my main set of tongs) until now.

When I first built my two burner forge, the burner manufacture lost my order and delayed it by about a month. As a bit of recompense, he gave me 3 bars of 1080 steel. I knew I wanted to make a seax, but trying to figure out what type was another issue. I am not sure what type it exactly is and it may be more of “in the style of” as opposed to “recreated or duplicated”. Either way, I am happy with my progress and hopefully this will push me to continue since I do have a desire to do more with smithing.

The blade is approximately 4.5 inches long with a 4 inch long tang. I plan on making the tang a bit longer so that I can extend it through the handle and peen the excess over to secure the handle in place.

I didn’t get any before pictures like I did with my other projects, but the picture above and the next one are after my initial forging and now I am cleaning them up with my belt sander. The dark marks are hammer marks where I attempted to lengthen the blade a bit.

The next two pictures show more clean up:

On the bottom picture I have taken a marker and drawn where I want to work on the shoulder, rounding it out and making it more even. I will draw the tang out a bit and straighten everything out. After I am happy with the tang, I am going to go back and work on the blade geometry a bit. Overall I am happy with the geometry, but I think I am going to make a little wood jig to hold the blade at a consistent angle.

Once I am happy with everything, I am going to heat the blade up to a cherry red and shove it in vermiculite in order to normalize the blade. After than I will heat it back up to a cherry red (I will have a magnet handy to try the magnet test) and quench the blade. With any luck, my blade will be hardened otherwise, I will try it again. Once done with the quenching I will temper twice, both times at 400 degrees F for 2 hours.

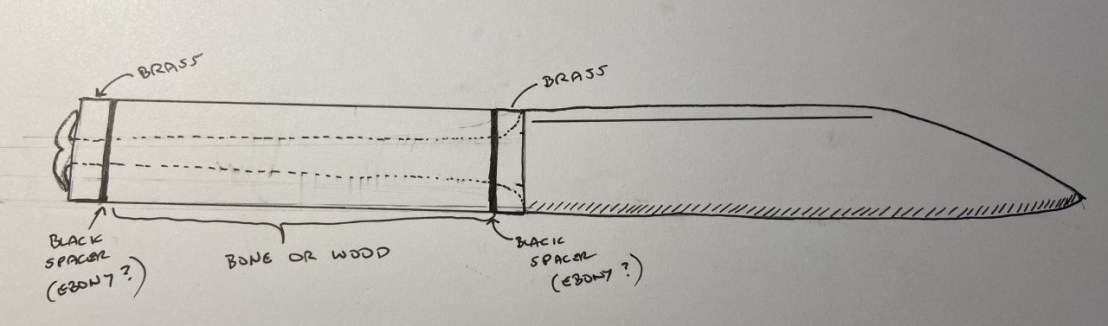

This is the overall plan for the finished look:

After I finish the blade I have a few friends that do leather working so I will probably hit them up and have them help me make an appropriate sheath.

More pictures as I progress…